This is a project I’m currently planning but have yet to execute.

Much to the amusement of some of my fellow loot- I mean volunteer janitors - at “the warehouse” I’ve been seeking out massive flat heatsinks for a lighting project. Since I scored a few …

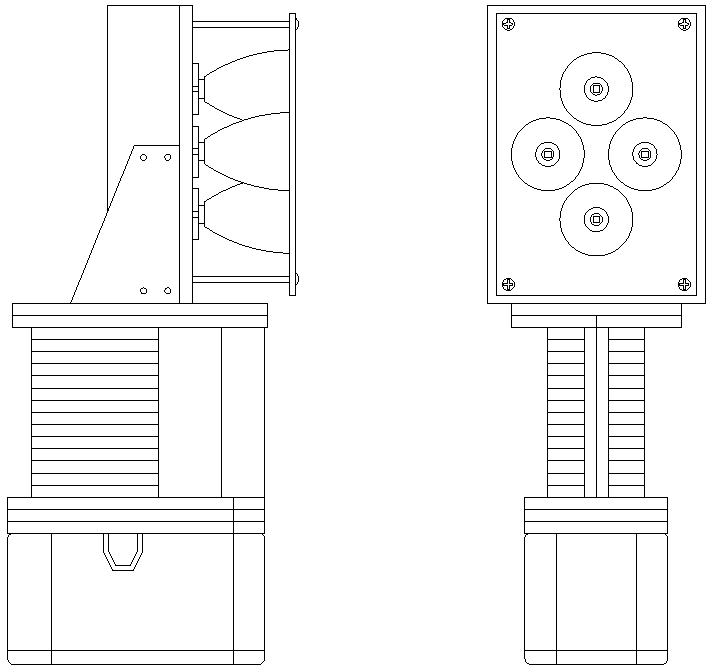

… I decided to start designing, using the trio of massive heatsinks in the background as my baseline

(anyone seeking high-power 300V DC to 15V DC converters, I have more than a few, sadly sans heat sinks).

I have a number of Ryobi ONE+ tools as well as an assortment of batteries for them. I’ve always thought the output of their HID spotlight is decent, but it’s a spotlight as opposed to a floodlight. While Ryobi does indeed sell a LED floodlight, I wanted to execute my own just because. And maybe to use as a general template for a spotlight too - also just because.

Initially I wanted to 3D print the battery interface/handle/body, but I’ve progressed little in my intent to learn the new 3D CAD packages. I’d like to get started sooner rather than Makerspace whenever, so I decided to do a rough version out of laminated plywood sections cut on one of the lasers:

4AH battery on the bottom that slots into the handle/body. Enormous heatsink on top with 4x LED/reflector assemblies. I need to source some decent 1/4" plywood - the sanded stuff that home depot stocks seems like it’s hardly a grade above their 3-ply rated sheathing.

In the event that anyone else is contemplating such an ill-advised project themselves, they should note that most Ryobi batteries have some sort of DRM built into them and will only put out ~8V until they “authenticate” with a Ryobi tool; the pair of 4AH batteries I have inexplicably don’t exhibit this behavior yet the other smaller batteries I have do (both with the fuel gauge and the pack-in batteries)

I have a tentative cut layout…

… and as you can see the innards are a tad more involved than the 2-view sketch suggests. I’m assuming

#8 x 2.25" wood screws for the handle: note the alternative patterns with a multi-pattern plate in the middle that will need to accept another pattern to ensure sufficient length. I’ll see if gluing strata makes sense. Missing: accommodations for a switch and driving circuitry.

I expect to use Cree XHP70 LED’s (12V) driven to reckless current levels (I expect ~24W per LED and ~12,000 lumens). I might be able to find something off-the-shelf for driving circuitry, which is preferrable to “rolling my own” since I’d like a more efficient DC-DC circuit as opposed to the current-limiting resistor and/or linear regulator approach that’s within my limited ability to fabricate.