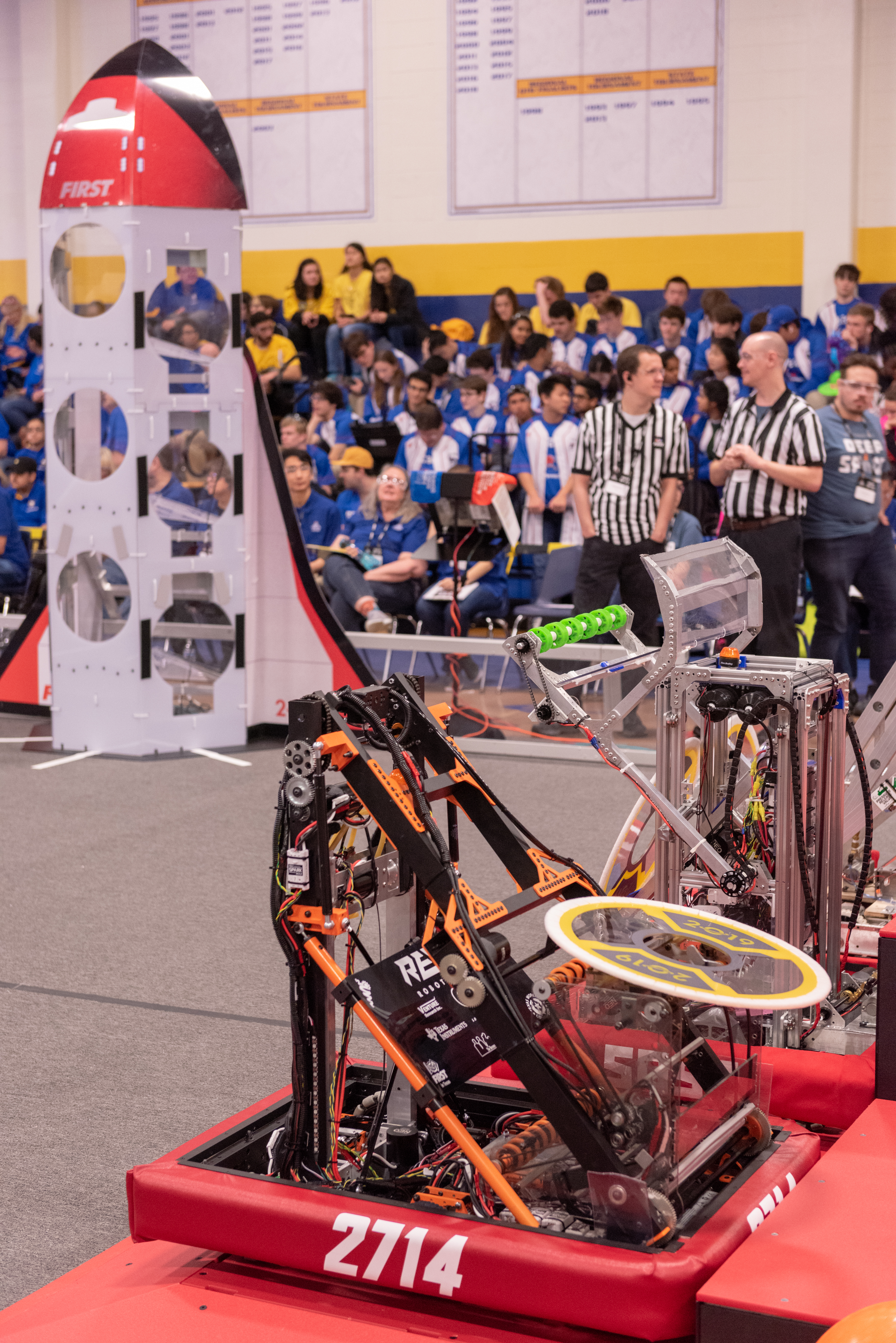

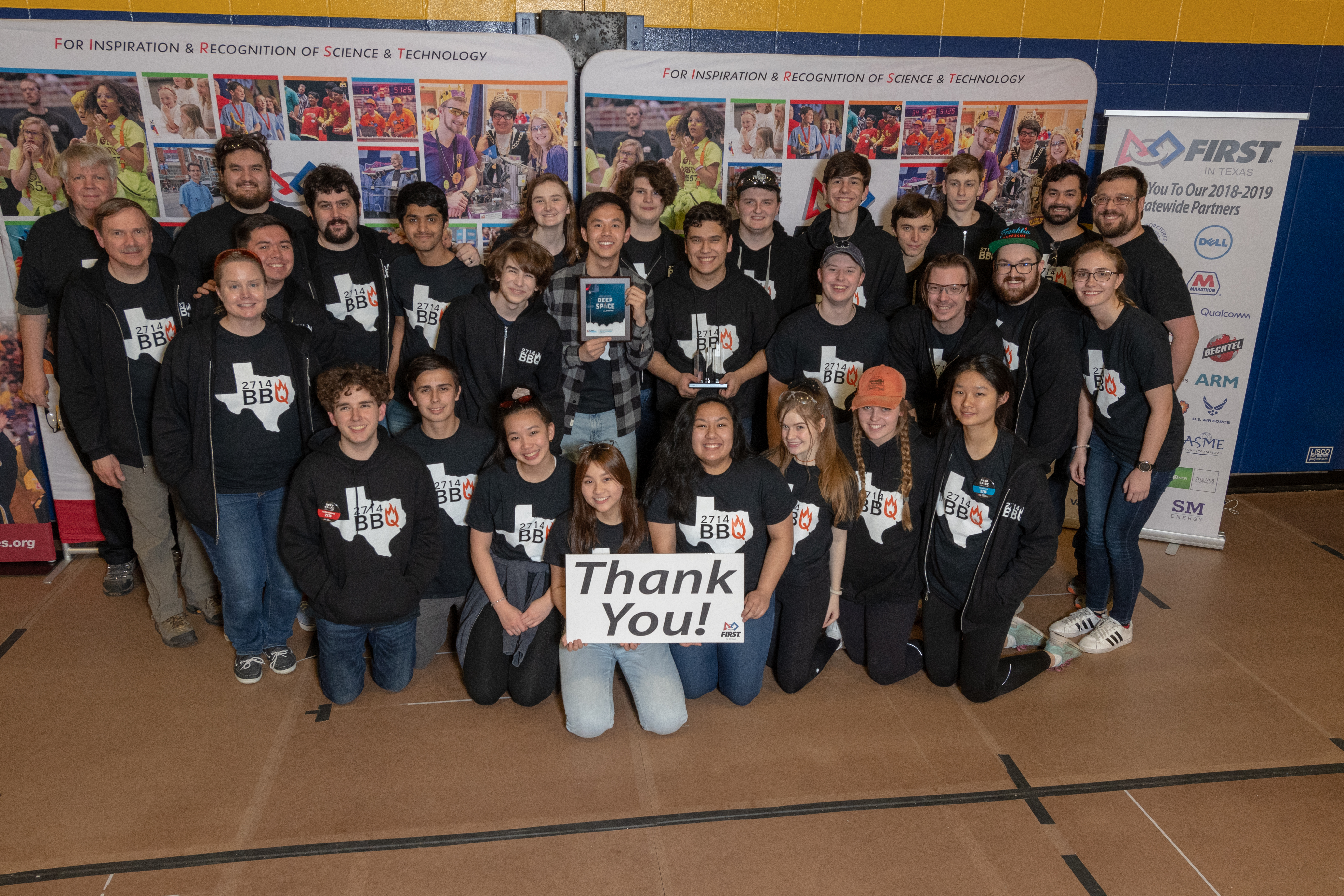

I mentor a High School Robotics team called “Team 2714 BBQ”

@abitamimbharmal Is one of the students on the team.

Dan Wolf, @greg and @EnDeR_WiGGiN are also makerspace members and team mentors. I would also like the thank @Dawsmart, @hon1nbo and @Luetchy for their help with the team.

This past weekend the team competed in their second event winning 1st place and qualifying for state championships. They also earned 2nd place during their first event. The kids have worked really hard on this robot and it has payed off.