Before I went home earlier it was acting weird. I spoke to Tim and he gave me some ideas, if it acts up again place a sign on it to read do not use

I’ve cut 3 signs today, and have cut another different sign after the errors I had. The A letters where the error occurs might have open vector or something weird. Sheetcam didnt give me any parts are not complete errors. It working fine otherwise.

Was it all the same material size??

Yes. 16 ga. I had the cut chart set for 16 ga mild steel. No fine cut since the fine cut settings aren’t correct

The power settings have changed since last week.

Last week when I taught the class, the 11GA/Mild Steel/45A power cut the test sheet perfectly.

Today, I had to crank it up to 65A to get a good cut.

Later, I tried to cut 1/8" stainless steel on 45A. There is no setting for 1/8" SS. So, I rounded up to the 3/16", using 45A. It did not cut through. Then, I tried cranking it up to 65A and it cut too much material, running too fast and blasting out too much metal.

Also, the laser seems to have been recalibrated so that the crosshair aims down to where the nozzle is exactly? At least, that’s what it seems like. Now, you cannot see the intersection of the crosshairs since the nozzle is in the way. There seems to be no offset.

And something about the Fine Cut tip isn’t working correctly. A member told me that there’s something wrong with it, but I still gave it a shot anyway. I borrowed his consumable and the Dynatorch keeps dragging the material back and forth as it moves.

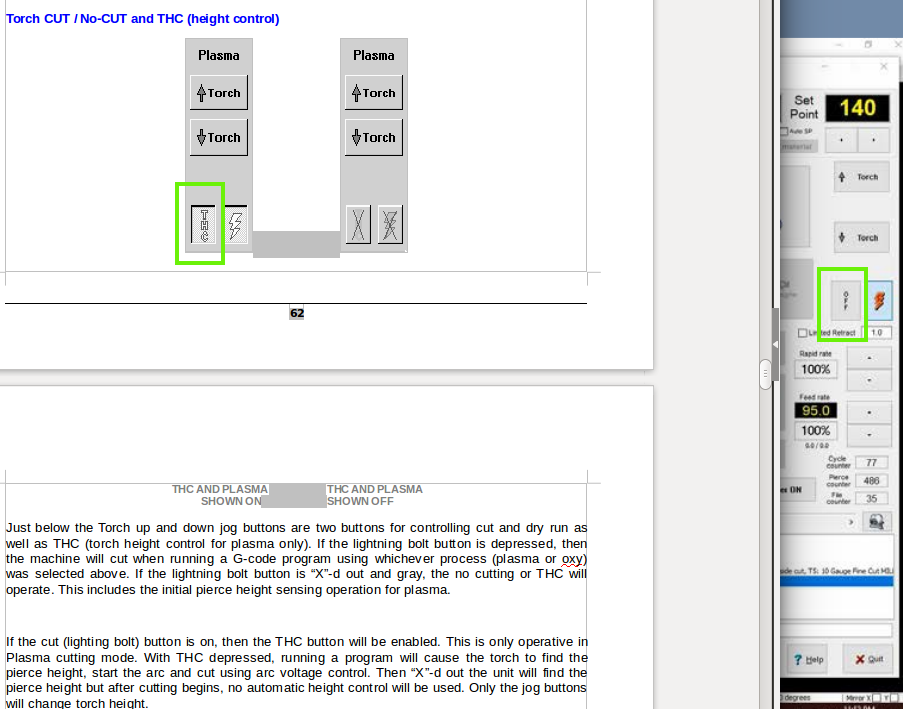

Just wanted to link this photo here, so as to maybe help with sorting out the button and its somewhat confusing status/behaviour

From this post:

Yep, if both of you are referring to the THC then I am sure it was enabled. It was only a problem with the fine cut tip.

Just to check, you had the appropriate fine cut swirl ring, fine cut nozzle, and the ohmic version of the fine cut shield, that extends below the nozzle?

So Friday, Someone was having an issue it. Turns out that someone had changed the selection in the menu. SO if you do not see multiple options for your cut selection, IE 45 amp consumables, 65 amp consumables & 85 Amp consumables. Then someone changed it.

I ran in to this issue when I was teaching last week. when I first went through the demo, it had all 3 Amp options. when a student followed my steps, there was only 45. I didn’t know why, then made the change in your photo. then the options showed up.

Help with the hypertherm would be appreciated  . It will not turn on for some reason. Please advise

. It will not turn on for some reason. Please advise

Never mind

Glad I could help.

Continuing from the other Issues Thread… It wasn’t liking me to grab just the post for some reason.

The life span on the consumables vary on many conditions.

Those are

- Material being cut.

- Amperage of the torch.

- The air quality of the compressed air.

- Distance of the arc to the material, IE how high or low the head is to material.

When I cut the open house keychains, there were 208 of them. That’s 832 pierces, 3,342” of cutting. The consumables were still ok. I did have to clean them probably a dozen times due to dross/slag. This is the downside of the fine cut stuff.

@coffeebean got her piece done but had to stop constantly to clean the tip on 1 medium size piece.

Is there anything we can to to prevent this in the future. Her 5 min cut literally took all afternoon. Someone mentioned they did not think the cutter was getting enough air, but the air is not adjustable.

I appreciate everyone’s input on this!

Would it be worth it to try some of the anti-spatter goo stuff that you can put on mig welder nozzles on the torch head? Could that help keep the nozzle clean?

Could we create links to these videos on the Plasma PC

Tips

When to Change Swirl Ring

When to change Powermax Electrode

When to change Powermax Nozzle

When to change Powermax Shield

When to change Powermax Retaining Cap

I guess I’ll ask what I’m finding to be an obvious question but which I haven’t seen discussed:

was the stock clean?

I know we don’t really talk about needing to clean stock with plasma cutting (unlike TIG), but dirty stock will spatter more, regardless the process…

This is a consumables chart that might be handy to have posted near the machine.

Powermax85 Consumables.pptx (373.1 KB)