The power settings have changed since last week.

Last week when I taught the class, the 11GA/Mild Steel/45A power cut the test sheet perfectly.

Today, I had to crank it up to 65A to get a good cut.

Later, I tried to cut 1/8" stainless steel on 45A. There is no setting for 1/8" SS. So, I rounded up to the 3/16", using 45A. It did not cut through. Then, I tried cranking it up to 65A and it cut too much material, running too fast and blasting out too much metal.

Also, the laser seems to have been recalibrated so that the crosshair aims down to where the nozzle is exactly? At least, that’s what it seems like. Now, you cannot see the intersection of the crosshairs since the nozzle is in the way. There seems to be no offset.

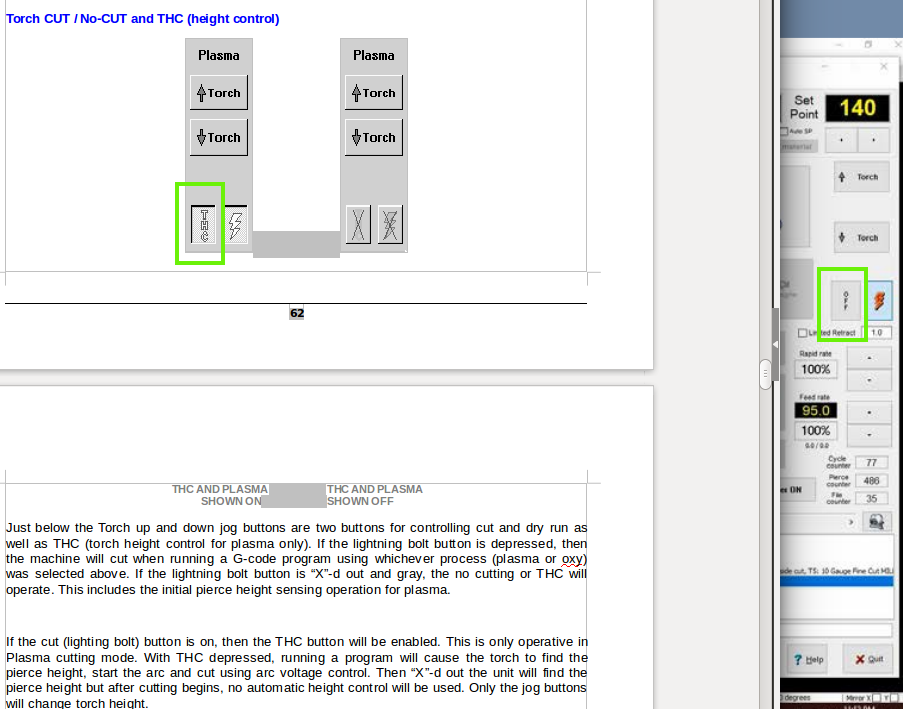

And something about the Fine Cut tip isn’t working correctly. A member told me that there’s something wrong with it, but I still gave it a shot anyway. I borrowed his consumable and the Dynatorch keeps dragging the material back and forth as it moves.

. It will not turn on for some reason. Please advise

. It will not turn on for some reason. Please advise