Yeah, if I can make it!

I build a DLP Resin 3D printer recently. I noticed that the UV output was not even across the projection. A mask can be generated in software that compensates for this, but I needed to know how the mask should look.

I build this device to profile the UV output:

It is a photodiode with a shortpass filter in front. The shortpass filter blocks all but the portion of the spectrum I am trying to measure. Here is a profile of the Transmittance:

The completed assembly:

Using it to scan the surface:

The output is attached to an opamp and I readout the value on my multimeter. It works great, and now I get consistent print results across the entire build surface!

(Cross posting here for blog’s sake)

Improved auto are tools and organization, now have complete 3/8 and 1/2 shallow and deep impact socket set along with some new torque wrenches

Nice! Do you have any pictures of prints? I would love to see something!

Hi! I’m new to DMS. My name is Bridget and this is what I’m making right now.

I have a small 3D printing company and this is a family’s Mother’s Day order: Wonder Woman is Grandma, and although she just thinks that the family had an appointment and that she’s getting her one bobble, on Mother’s Day all the kids are going to present them to her as well (all mini bobbles except for the Snow White queen).

It was fun to work on because I’ve never had so many people from one family to scan other than my own, who then wouldn’t sign model releases and let me photograph them altogether! These folks were cool about it!

Not much but I made my buttons for my co-workers. It’s a goofy pic of one of my best friend, used to be co-worker.

Well Linda Carter is more then old enough to be a grandmother. Very cool use of scanner!

Wow,

I didn’t realize it simmered. Thanks for the detail shot. Great work as always, you really step up this Table Top Game lifestyle.

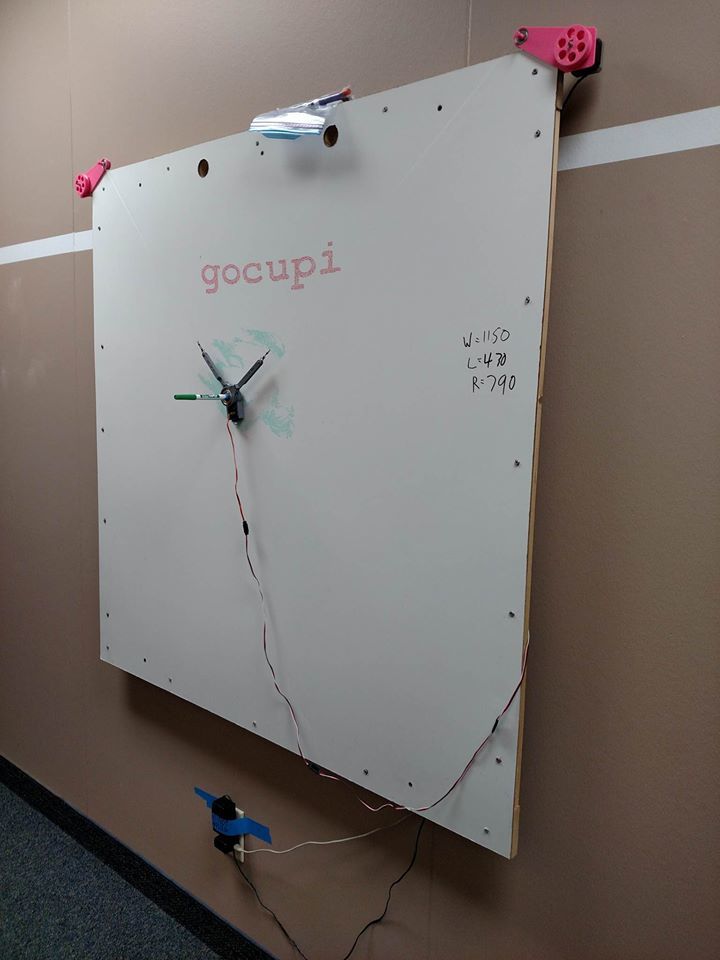

For the Makers Make and upcoming 3D printing and electronics art shows, I have mounted a customized Gocupi polargraph whiteboard drawbot on the wall in the hall way off the common room. As you know @Brandon_Green and @Brandon_Dunson had a very successful kickstarter with their open source polargraph that runs off a Raspberry Pi, with software written in Go, with the ideal that the motor pulleys can be suction cupped onto a surface. I redesigned the motor mounts and pulleys using Solidworks which I learned how to use thanks to @Dawsmart. He also helped me hang the whiteboard on the wall securely, Thanks!

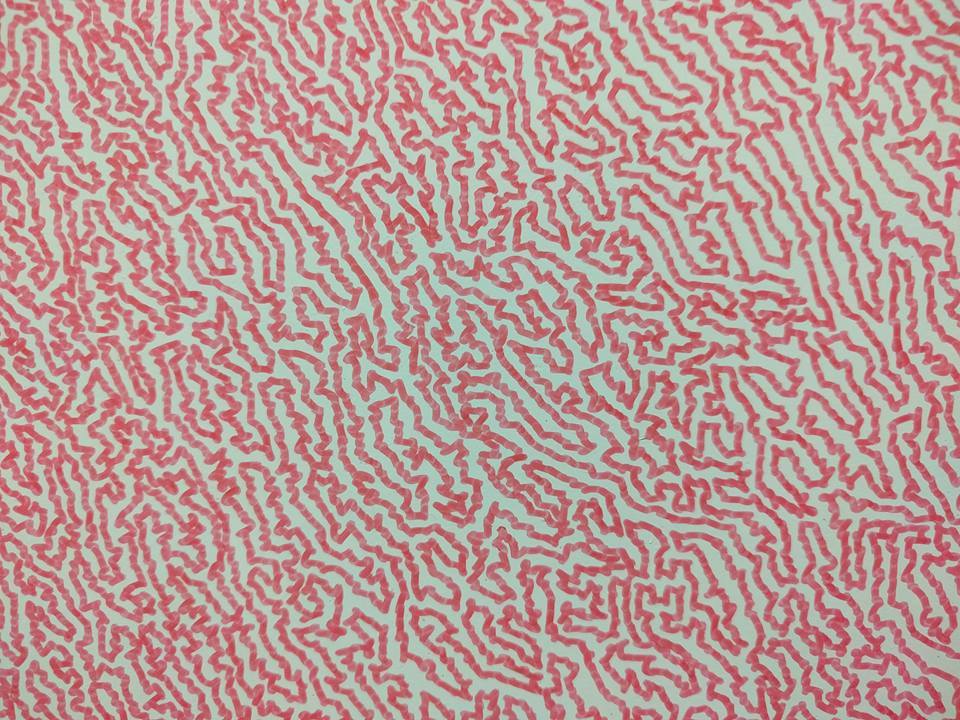

As you guys can see it’s a work in progress, I try to keep it updated with different images, here is the current image (which has since been catified :3 )

Here’s on the first iterations using the original gondala design, I since printed a new one I found on thingiverse.

Here’s my doppleganger. Thanks to Julio for the picture.

Enhance! Enhance!

I posted a few things in last months thread. I’m in the process of some new designs now  I’m wanting to get into casting my parts.

I’m wanting to get into casting my parts.

How it… Turned out?

Lidded box turned last night from black locust, thinking about a class on these. Lots of fun and limitless design possibility.

A couple of bowls made from the maple in the back of the wood shop.

Vessels and thin natural edge bowls. All in various states of receiving a finish.

Matt, it was a pleasure watching you work on the Powermatic Lathe last night. You make some beautiful wood work. Let me know when you class is, I want to be in it.