OK.

So, yeah, having not been able to be a part of the class, I have no knowledge of that, which makes perfect sense.

I am making a 40 amp discharge light rig to make it faster to store the lipos if they haven’t been fully used, say because we blow up the gokart motor for example. (The charger only discharges at .5 amps)

My question is, is it excessive to put 40 amps through a 12-10 awg crimp on ring terminal? I couldn’t find any specs on what is recommended. The setup is 3 12v 20w g4 bulbs in series times 12 in parallel, 36 bulbs total (~13k lumens…)

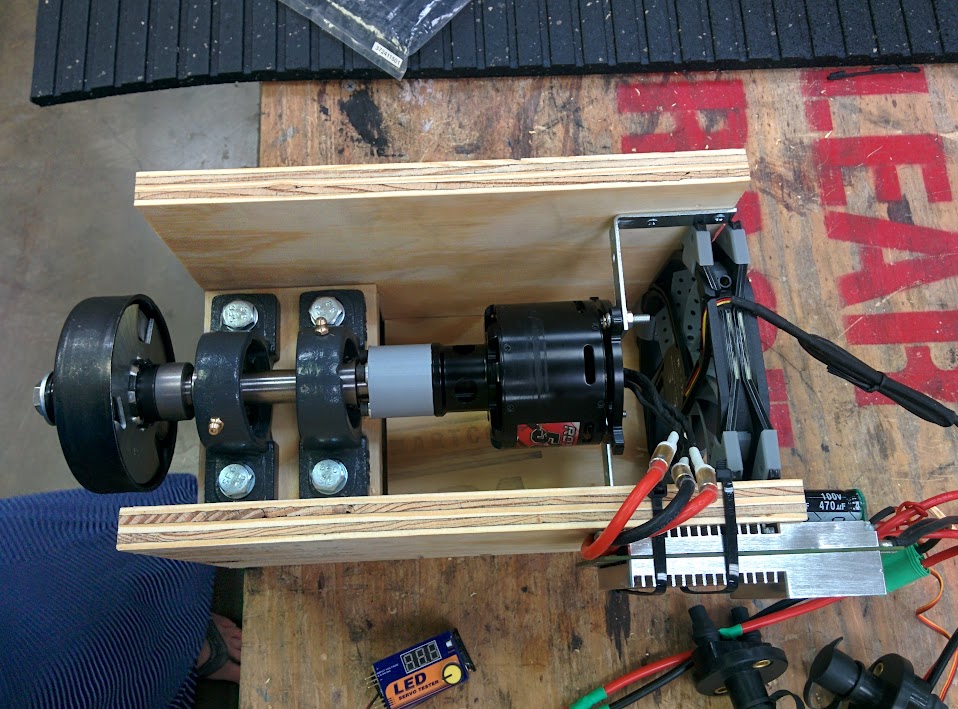

We got in our 40" wide 1" rear axle, wheel hubs, sprocket, bearings.

Looking at this much mass that has to start spinning from 0, I will be amazed if we dont have to go with a centrifugal clutch so that the motor can spin up to a thousand rpm before engaging.

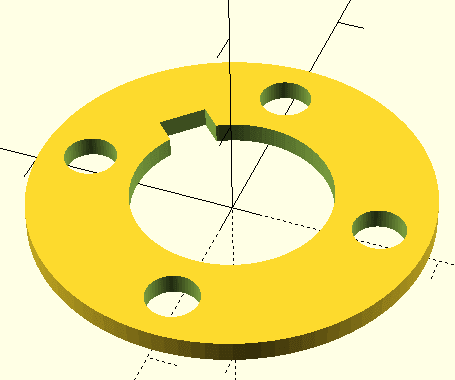

Also after measuring the motor hub, turns out the bolts are farther out than the 3/4" shaft, so all we need is a collar like the following to coulpe the intermediate shaft to the motor, and the only modifications to the intermediate shaft would be boring a 10mm hole in the middle so it slides over the motor’s silver shaft.

Would anyone like to 3d print the above collar and see if my measurements line up with the motor hub? I wonder if a really tall 100% density print would work on the actual kart… All of the torque would be going through the contact surface of the 3/16" rectangular key, anyone know what psi abs plastic can withstand without deforming?

$fn = 100;

$boltPatternRadius = 28.575 / 2; // 1.125 inches

$boltRadius = 5 / 2;

$shaftRadius = 19.05 / 2; // .75 inches

$collarRadius = 38.1 / 2; // 1.5 inches

$keyWayWidth = 4.7625; // 3/16 inches

$height = 2;

difference() {

cylinder(r = $collarRadius, h= $height);

// All of the negative space

union() {

// bolt holes for(angle = [0:90:270]) { rotate([0,0,angle]) translate([$boltPatternRadius, 0, 0]) cylinder(r = $boltRadius, h=$height); }

// key way rotate([0,0,45]) translate([$shaftRadius, 0, $height/2]) cube(size=[$keyWayWidth, $keyWayWidth, $height], center=true);

// 3/4" shaft cylinder(r = $shaftRadius, h= $height);}

}

Someone let me know if the following analysis sounds plausible at all

From what I could find the compressive strength of ABS plastic is 65 Mpa or ~9,500 psi, lets say 5,000 psi for a printed part.

The radius arm of the key is 0.375 inches, and the surface area is 3/32 wide * 1 inch tall = 0.09375 square inches, so to find the max torque an abs coupler could be expected to survive would be 5000 = x / (0.03125 * 0.09375), so as long as the motor is putting out less than 14.6 foot pounds of torque a plastic coupler might work. Now we just need to rig up our electronic torque gauge and measure the power of the motor from a stop, I’m not sure what to expect

Am I understanding properly this is 2" thick?

Should be easy enough to do in aluminum, too, in the HAAS, except the keyway, if you find the plastic won’t hold up. Heck, this should be fairly easy in steel, even by hand. Again, the keyway seems the hardest…

My physics skills are far too rusty to refute or confirm your calculations, but I do wonder if the parts will get too hot…

In regards to your electrical question, I’d point out that the NEC requires 12ga wiring for 20A circuits and IIRC 10ga for 30A. I’d say you’re probably safe, but make sure those crimps are good and tight, and monitor the temperature of things the first time you use it.

Using 12AWG is fine for short distances like in this case. Not sure about the crimp connector though. Be careful when discharging the batteries. Most loads intended for LiPo batteries have an automatic low voltage cutoff. If the bulbs are connected directly to the batteries it would be easy to damage the batteries. Good thinking though, could take all day to discharge at half an amp!

Got in the remaining components so we can mock up the full drive train this weekend, we are getting closer to finding out 1) Is a centrifugal clutch on an electric motor crazy? 2) What will fail first, the motor, the electronics, or the not at all rated for high speed bearings I got for the intermediate / jack shaft

We made lots of progress tonight, got the intermediate shaft cut down and bored out on both ends

And the 3d printed coupler looks plausible

But I think due to a combination of my knocking it off the printbed with a heavy object before it fully cooled and overzealous torquing of the bolts I managed to skew the whole coupler, enough that I didn’t even try spinning up the motor. At least I’m hoping that it’s not due to the 3d printer itself, about to try again on lefty.

Edit - Nope, turns out the lefty printer was not printing squarely

Also the light discharge works great, although I would recommend not looking directly at it (welding goggles help) and to have plenty of ventilation to keep the lights cool. It’s important to always have the low voltage alarms plugged into the balance leads, stopping at ~3.65 volts under load seemed to result in ~3.85 volts per cell, and only a quick balance on charger storage mode and they are ready for storage. The wiring seemed to handle the guesstimated 40amps with no problems, didn’t warm up at all.

You know I just converted inch pounds to a unit I am more familiar with, foot-pounds, and all of a sudden that chart above doesn’t seem sufficient for a go-kart if the range is where our motor falls…

60 inch pounds only equate to 5 foot pounds… A mini cooper has about 115 foot pounds of torque at 4,000 RPM

Yeah, but it weighs 1.3 tons curb…

That’s 22-1/3lbs per lb-ft of torque.

How much is this kart going to weigh?

If it’s less than 113lbs, they’ll have similar acceleration, except the electric hits max torque from a standstill…

edit: Oh yea, except for the driver @ 200lbs avg.

Actually it only weighs about 1,400 pounds or about 0.7 tons.

But the rest of your point is valid, I hope. Although in the above chart it only has about 2.5 foot pounds of torque at 2,000 RPM.

10" wheels at 30MPH need to be turning at about 1000 RPM. If we assume a 2:1 gearing ratio. That would mean that we have 5 foot pounds of torque available at the axle at 30mph. And 10 foot pounds of torque at the axle at start. I’d estimate from what I have seen so far that the kart with rider will be about 400 pounds

So, we can estimate the acceleration for the cart with my assumptions as

Tire diamter = 0.833 ft

F = T/R ~ 10 ft-lbs/0.4165 ft ~ 24 lbf

a = F/m ~ 24lbf/400lbm ~ 0.06 ft/s/s

If my math is correct that means the cart will have about two orders of magnitude less acceleration than a typical car (about 6.5 ft/s/s)

Anyone else care to check my math?

I forgot to compensate for the difference between LBF (force) and weight (LBM)

1 LBF = 32 ft-LBM/s/s (or mass in pounds time G)

so the above equation should be 24 lbf * (32ft-LBM/s/s) / 400 LBM ~ ~1.92 ft/s/s

So we are only about 1/3 of a cars acceleration if the rest of my math and assumptions are correct.

Dang, it has been a LONG time since I did these kinds of calculations… @frank_lima would you care to double check?

So again, it should take our kart about 15-16 seconds to get to 30MPH if all of the above is correct.

My apologies. Without double checking the output figures you gave I simply assumed you meant a modern Mini.

So for today’s mini we are talking 162lbs-ft @ 1250 RPM and 2605 lbs.

So more like 16lbs per lbs-ft…

For what it’s worth, this all sounds on par with the typical 'tween / young teen go-karts of yore running the commonly available 3-5 hp B&S motors. Their torque output in lbs-ft was pretty much the same as their rated hp without some tinkering…

Don’t forget about the"ground effects"of driving a vehicle with your butt just an inch or so from the ground and in the open air. That adds roughly double the speed, halves the acceleration to speed times, and generally ups the fun factor. It’s what sells Morgans, Ariel Atoms, CampagnaT-rexes, and most motorcycles…

Sorry, I wasn’t aware there was a difference in weight. I just did a google search for small cars and came up with the numbers for the mini I referenced. Never really be a ‘car’ person.

Wasn’t aware what the torque ratings were on 3-5 hp B&S motors, but as I recall they seemed much faster then what we are talking about for this go kart (ie >45mph)

Got the motor mounted in a test box, now just need to secure the axle to something to test it out driving the axle. Here is a video of spinning it up to full speed (should be 7.5k rpm, but havent confirmed that) for a few seconds with no load

Brandon & Space Kart Team,

An impressive job of design / prototyping / digital manufacturing.

After I read the description a while back, I really wished I could have taken this class but I had too many Saturdays booked up in advance. It did inspire me to take a short course in Solidworks offered at Richland, but I hope Mr. Frank Lima offers this again soon.

JAG “All Physical Objects In the Universe Begin As An Idea” MAN

We clamped the Drivetrain onto the pallet jack to test it out, amazingly it worked