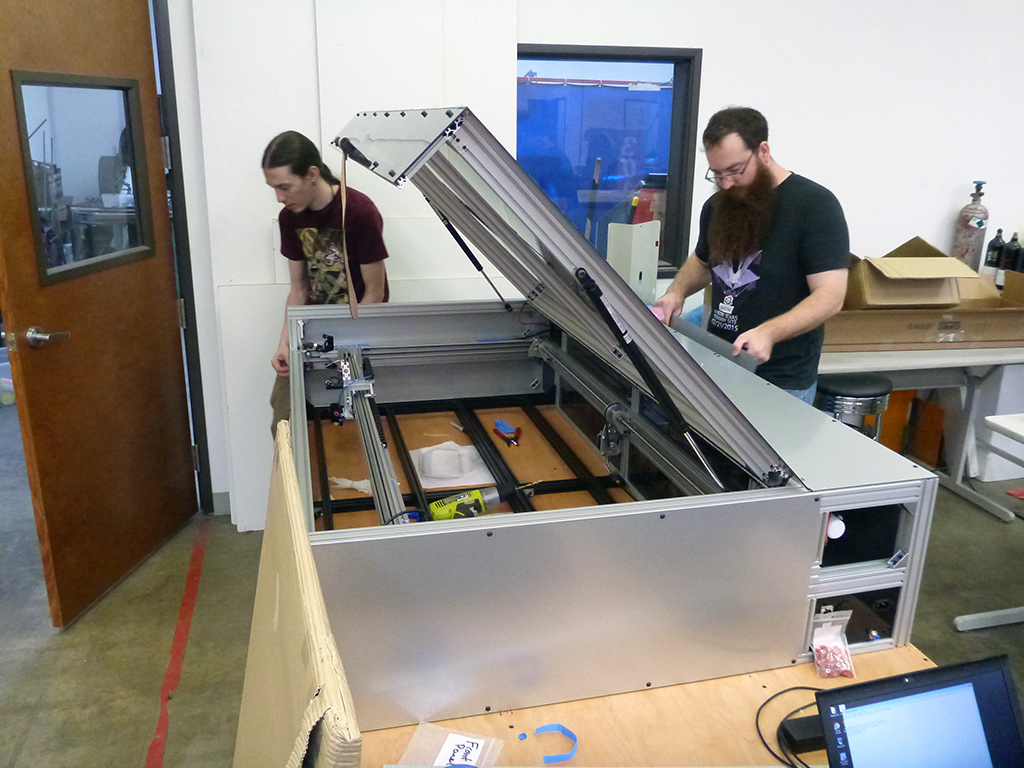

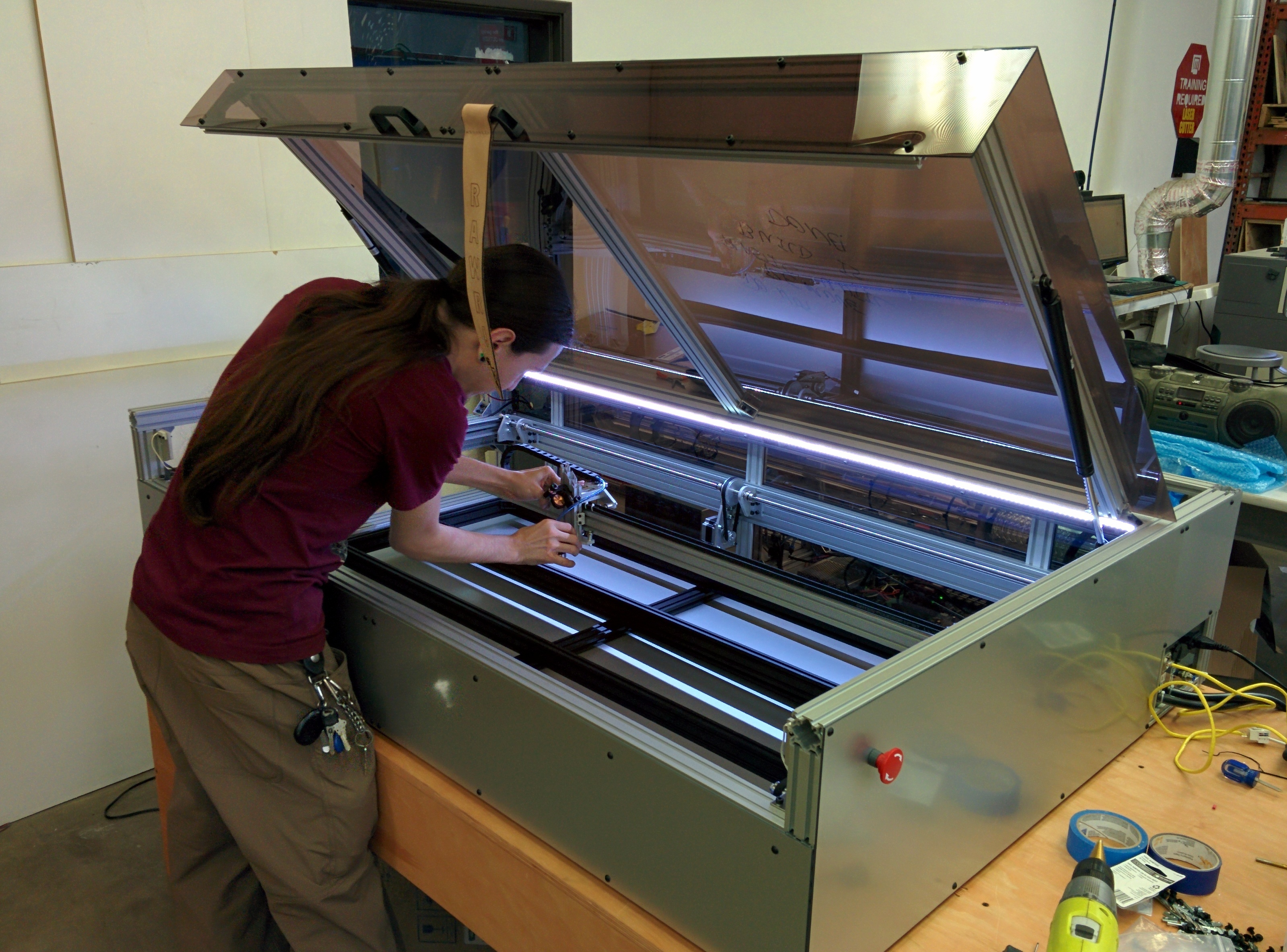

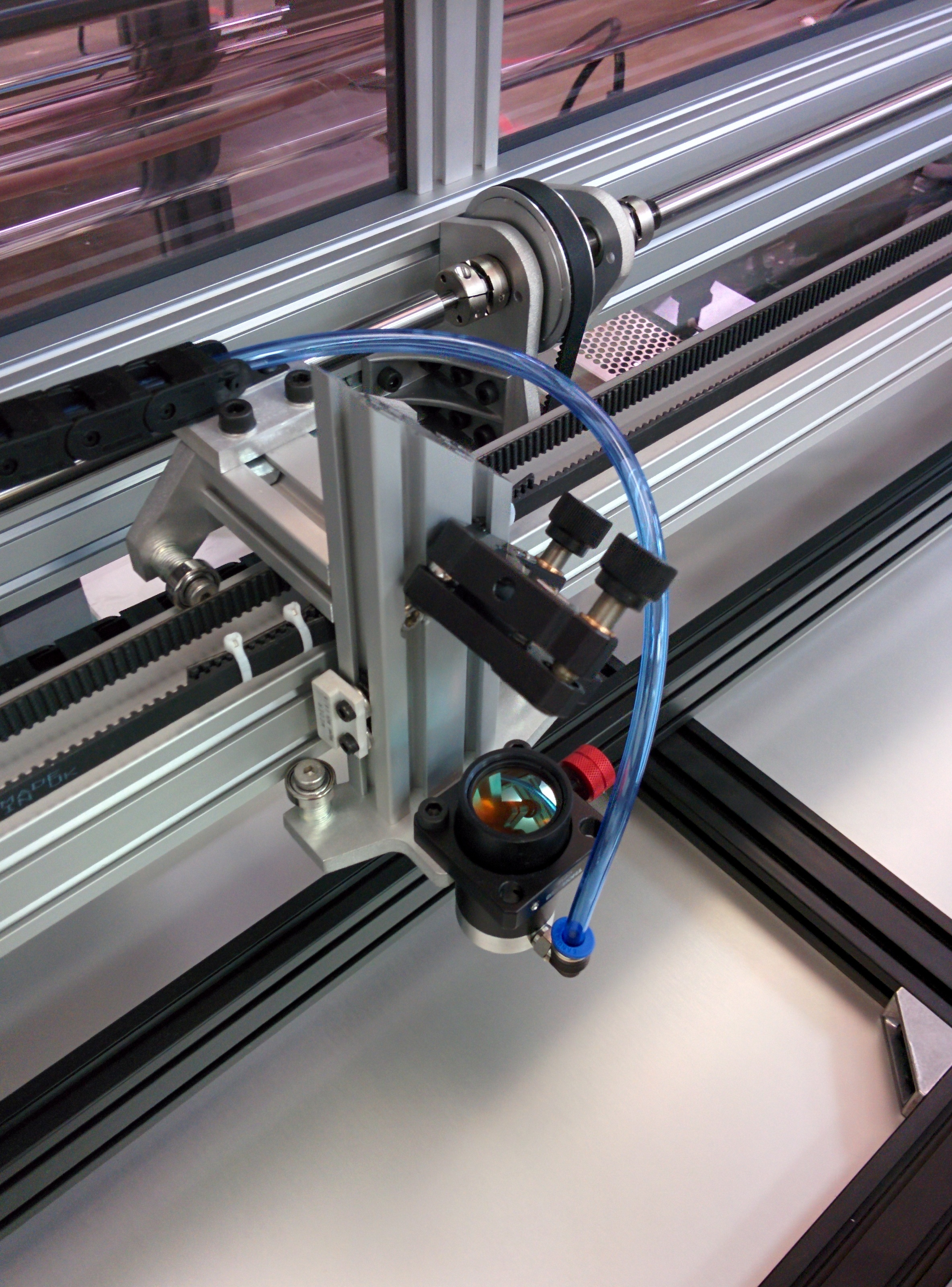

All parts from the bill of materials have arrived for the Lasersaur. Build sessions can begin soon. Two things need to happen prior to the build sessions: clean up the laser area and build or acquire a worktable. The status of the stuff on the wiki has been updated.

https://dallasmakerspace.org/wiki/Lasersaur_Laser_Cutter

If anyone is interested in building a sturdy worktable please see William for funding. It needs to be approximately 4’ by 8’ and able to hold 400 pounds stably to accommodate the Lasersaur.

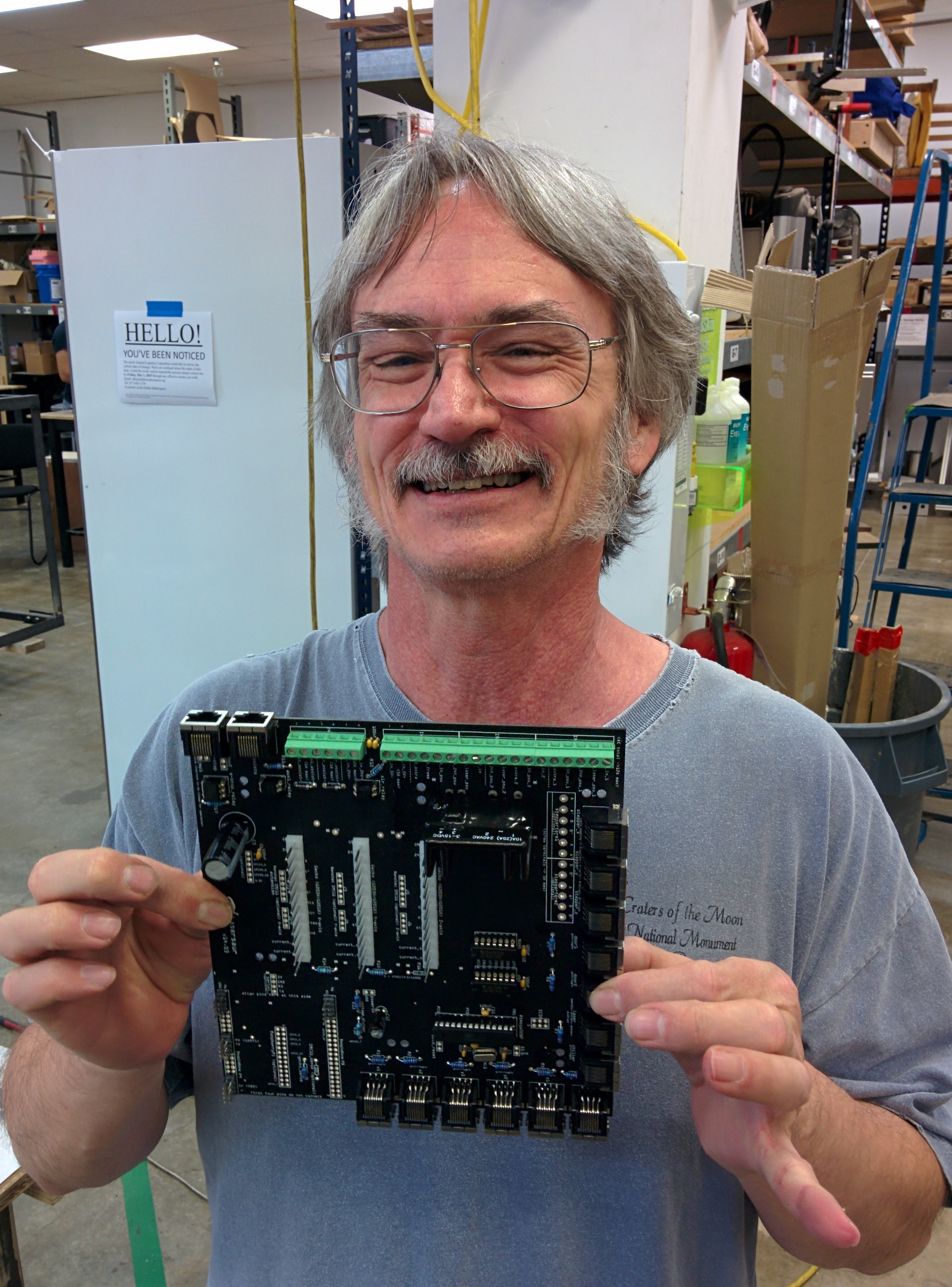

I’m thinking Thursday evening we can clean things up in the laser area and build a worktable. Possibly begin building the Lasersaur if those things are accomplished. Some of the other parts of the Lasersaur can be constructed concurrently like the motherboard which is all through hole-components with a few IC that need sockets. Perhaps the electronics committee or a skilled member wants to assist with the motherboard?