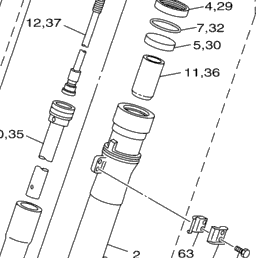

I have a lower end of a shock from a motorcycle that has a slight imperfection on the inside - looking for help to bore/hone it until the shock has full travel. Willing to pay a little money to anyone that would know how to do this procedure.

Thanks,

Brian Kleinfall