That is how I read and remember the sequence. @Brandon_Green can you confirm?

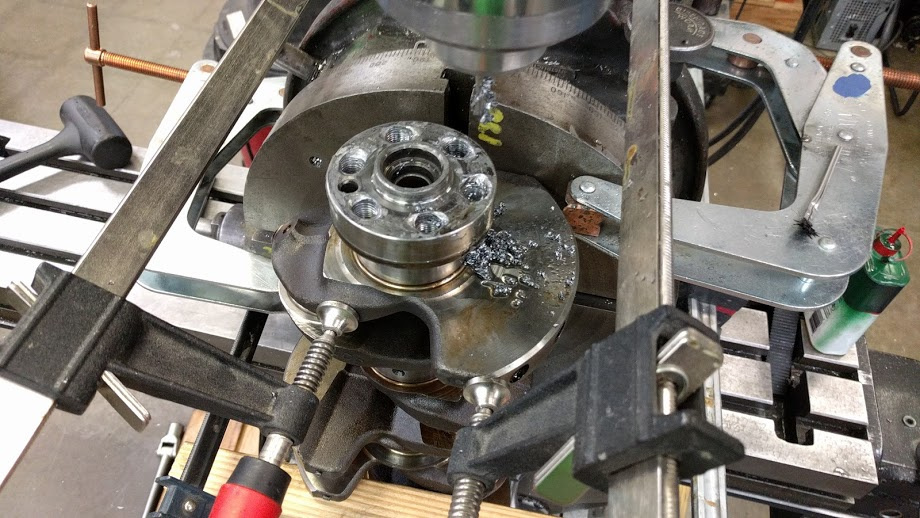

Yeah, we are just now getting to measuring the parts we think were causing the noise

Looks like the number 3 piston rod bearing was the likely issue, the others looked slightly worn, but number 3 had chunks missing out of it

The spec on the head says 4 thousandths out of flatness is ok, it was about 8 thousandths, so feeling adventurous we took off about 9 thousandths using the bridgeport. a large fly cutter would have been preferable to the face mill, plus the head being not perfectly perpendicular to table meant there was a visible but barely measurable ridge along each pass.

Some cleanup and it seemed to turn out ok (much cleaning and valve lapping still to be done of course)

Amazingly there is next to no wear on the crankshaft or in the cylinder bores, everything measured to within factory spec. The Rod bearings grade info stamped on the crankshaft was 1 1 0 0, but they measured out to all be almost exactly the same and the factory service manual says grade 0

How much do you think you may have increased the compression ratio by doing that? I suppose I could look up the bore, stroke and combustion chamber size…

8.73:1 up from 8.6:1 at most

Because you weren’t the only one wondering

Really that low? I think I have a factory 4 cylinder VW engine running around 10:1 with 15 lbs of boost on premium pump gas.

According to wikipedia it was the KA24E (single cam) that had a compression ratio of 8.6:1, our KA24DE says 9.5:1

Now that the head height has changed - will you be checking to see if valve pockets are needed?

We already have those

I meant the “intentional” type - not the “what is that noise?” type:fearful:

Tomorrow will be trying to extract the sheared off flywheel bolt from the crankshaft (got some left handed drill bits, extractors, bottoming tap), inspecting valves, and verifying remaining measurements before making a list of what to order to start reassembly.

Not surprisingly this plan failed, tried to indicate the crank perpendicular to the endmill but as you might expect a few woodclamps were not sufficient, so it shifted and ended up milling off most of the threads on accident, but at least the sheared off bolt has been removed, helicoil time!

I should have commented earlier on this one, but welding on a nut as a new bolt head works exceptionally well. Not only do you have a new head for your wrench, the heat involved usually loosens up the bolt at the same time.

I have done this before on a steering knuckle and it worked like a champ. Remember to use a non-zinc coated or stainless nut to avoid zinc fumes.

Yeah I forgot about that. I’ve done that a few times.

And here we see the KA’s biggest disadvantage: Half-counterweighted crankshaft. If it only had full counterweighting, the things it would be capable of.

The use of fancy tools is nice, but remember the golden rule: Keep It Simple, Stupid. As zmetzing pointed out, welding a nut onto the remaining bolt head would have probably been easier and wouldn’t have you trying to helicoil a balanced rotating mass. As for the rod bearings, I’d probably have a professional take a look at the crank. If material was taken off of the bearing, the corresponding journal probably bears some kind of witness that you should have repaired, if you want this engine to last under endurance racing load.

On the topic of compression and valve clearance, .009 off the head shouldn’t cause a need for special consideration, as long as the engine is timed properly when reassembled. Much more and I’d start looking at thicker head gaskets. And, as stated, the Japanese RWD KA24DE has 9.5:1 compression stock. Please note that the Mexican RWD and all FWD variants have differing specifications. Additionally, the quoted figure for KA24E is only for FWD and Mexican-built RWD blocks; the Japanese RWD block in 240SX has 9.1:1 compression, though some documentation points to some late 1990 models, just prior to the mid-cycle (chuki) refresh, also had the 8.6:1 compression ratio. It should also be noted that the use of KA24E pistons in a KA24DE will grant either 11.1:1 or 11.6:1 compression, depending on source engine. This may be a worthwhile consideration, if a high octane fuel (>93) is available at the track. Along with a bit of intake and exhaust work, this can add a few cheap horsepower.

With Allen’s help talked to a local machine shop (City Motor Supply just south of DMS) and will be dropping off the block to be cleaned, inspected, bored, honed later this week. The new valves should be in for thursday night so we will be lapping and installing those.

Got the valves lapped, most of the other parts have arrived (felpro gasket sets and mahle clevite bearings), so next week should be able to start reassembly of the bottom end (dry fit plastigage test first then final assembly)

Can see a big difference before and after

Won’t be able to meet tonight, not sure if we will get the block back today or not.

We have the block back and all the parts to begin reassembly thursday night. Annoyingly RockAuto sent one valve different (someone had returned a different part in the correct box) from the others so we couldn’t finish reinstalling valves and springs in the head last time. The replacement from RockAuto was also the wrong one(probably a whole batch of wrong parts returned to them previously), so I had to order the valve from a different vendor.

An open question is if it would be worth the time to get the crankshaft ground (reducing its diameter on rod and main journals to ensure roundness and consistency), there are no visible defects or out of roundness that we could detect with the micrometer.

This is one of those things a good machinist could answer - if it is within spec - then perhaps a polish or use as is.

You may want to make sure undersized bearings are readily available as well (I ran into a “there are no bearings other than std size available” - long ago on a Porsche crank-but thankfully I had a fantastic machinist)