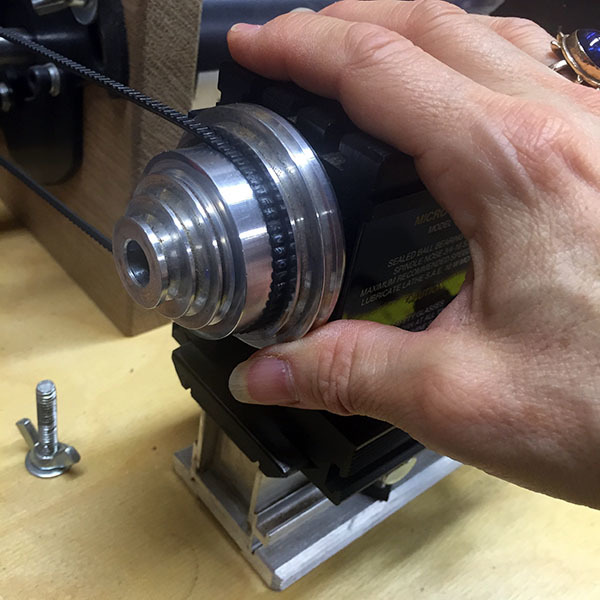

Seeking something suitable for a 2’ish inch diameter pulley on my lathe.

Yes, there’s one in the automotive toolbox last I checked. It should be in the large drawer in the bottom left.

Chris, if that puller doesn’t work, I have a few at home I can lend you.

Can you post a photo of the pulley you want to remove ?

Unimat lathe?

123456

Close. Taig Micro lathe.

Ah, can’t help you there… I have a couple extra parts for my Unimat. It was a steal on Craigslist at $150.

I have a Taig mill and the pulley is held on with a set screw, no puller tool required to remove it. Is there a set screw hiding somewhere? Tried just pulling it off after removing the set screw?

Haven’t tried yet - just getting ready for a project. I plan to make/put on an indexing wheel, and Nick Carter strongly recommends using a gear puller. But like you said - I saw there is a set screw and I’m just trying to be prepared for the possibility. I hate to get there to work on it and find myself unable to disassemble.

try the removing the set screw and using a soft blow hammer if it doesn’t move with just your hands.

I replaced the motor drive pulley on a friend’s wood lathe a few weekends ago and it was a keyed shaft that required a little more force to remove but not difficult.

I had a Taig many years ago and at that time, the pulley was heated up before being slipped on the shaft. It was a very tight fit. It also used a set screw. Even if they have loosed the fit, unless they have a flat on the shaft for the set screw, it will have raised a bur. It most likely will not just slide off.

When I had to remove mine I used some metal strapping with some 1/4-20 hardware to jury rig a gear puller. But I swear I have seen the appropriately sized gear puller in automotive tool box.

I had read exactly what you’re describing. I hope to file a flat on mine while it is disassembled.

This thing was unbelievably hard to remove, but we were successful. It took several different gear pullers in succession to finally remove it. There was almost no clearance between the pulley and the headstock, and as @wandrson predicted, that booger was really stuck on there. I have subsequently filed a flat where the setscrew intersects the shaft and it goes on and off easily now.

I posted the completed project with the indexing plate / pin / alignment block in the August Show & Tell.